is a leading business partner with technology and production capabilities.

is a leading business partner with technology and production capabilities.

offers flexible modules with progressive

offers flexible modules with progressive

mechanical solutions, including mobile phones, laptops, tablet PCs, eReaders and eNotes, etc.

We successfully developed a foldable hinge mechanism through years of collaboration

with a global OLED flexible display maker and global set makers.

One-stop systems from design to assembly

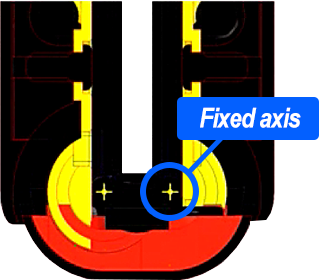

Fixed-Virtual Axis Structure

Improved bezel thickness and appearance by moving the hinge to the bottom of the panel using the world's first virtual axis

※ Retention of original patent for semi-circular rotational structure

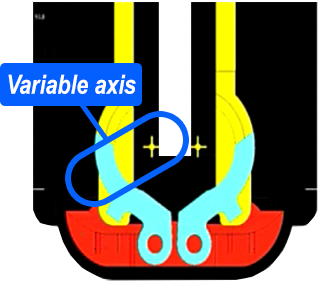

Variable-Virtual Axis Structure

Technology that minimizes the stress on the panel by

control moving the virtual axis for the first time

in the world and improves wrinkles that occur during folding

※ Retention of original patent for semi-circular rotational structure

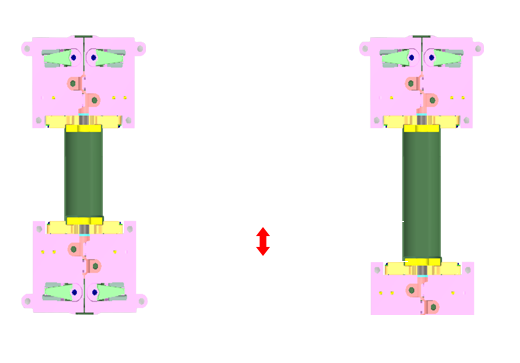

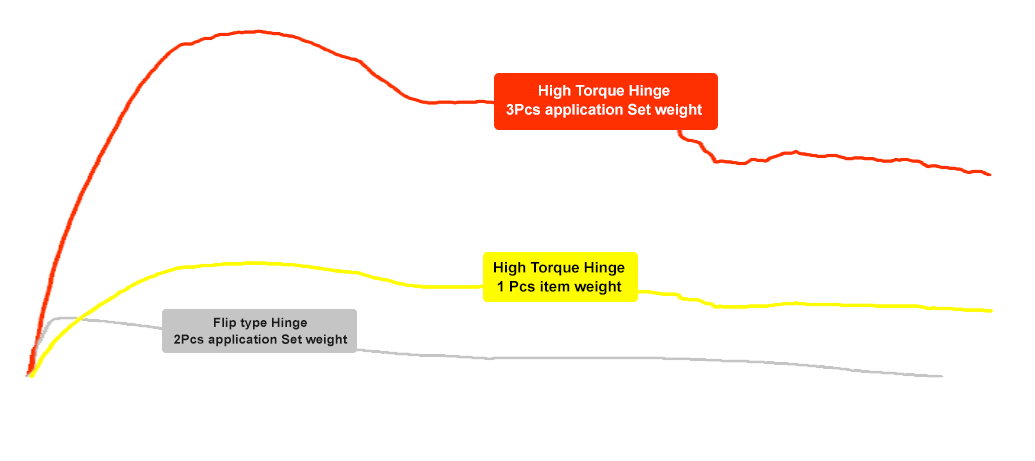

High Torque Hinge

Cost reduction (Single Hinge)

IT Extended Hinge

Hinge technology that can produce 4x higher

torque than traditional foldable hinges

Securing high torque and reliability necessary for realization of foldable devices with large displays such as tablets and laptops

Reduce device weight and cost and flexibility in implementation design by reducing the number of hinges and mounting space installed in foldable devices with High Torque Hinges

" Metal powder + Binder= Feed Stock .“ The process of mixing binders and metal ingredients using MIM-dedicated mixers.

The process of molding the desired shape by putting the mixing raw material into the injector

The process of removing a portion of the inner binder put in the de-solution in a solvent extraction method of removing the binder of the injection product.

The most commonly used heating removal method of removing the binder of the injection product is a process of removing the binder component inside the product by heating.

The sintering process that increases the inter-metal bonding force by elevating the temperature to obtain the desired dimensions and strength as a final step.

MIM parts are connected to be assembled and inspected. Customer shipping process after Packing.

AUFLEX CO., LTD.

HYUN-MIN(EDDIE) PARK

THE COMPANY’S CUSTOMER MARKETS

COMPRISE RETAILERS, ENTERPRISES,

MUNICIPALITIES, UTILITIES, UNIVERSITIES,

BUSINESSES AND OTHER

HIGH TECHNOLOGY MANUFACTURERS.

77, BANWOLLAM-GIL, HWASEONG-SI,

GYEONGGI-DO, KOREA